| Availability: | |

|---|---|

UTM-10ED

EBP INSTRUMENTS

Shanghai

90 sets / month

TT in advance

1 set

Specification:

Model | UTM-10ED | UTM-20ED | UTM-30ED | UTM-50ED |

Load frame | ||||

Max. Load(kN) | 10 | 20 | 30 | 50 |

Tensile space(mm) | 800 (can be customized) | 700 (can be customized) | ||

Compression space(mm) | 800 (can be customized) | 700 (can be customized) | ||

Test width(mm) | 400 (can be customized) | 500 (can be customized) | ||

Travel distance(mm) | 1140 | |||

Working temperature | +10 ... +35 °C | |||

Conformity | ISO 9000 and CE | |||

Force transducer | ||||

Load accuracy | Class 1 | |||

Load range | 2%~100%F·S | |||

Load resolution | 1/500000 | |||

Displacement transducer | ||||

Resolution of deformation | 0.04um | |||

Accuracy of displacement | Within±0.5%of indicating load | |||

Resolution of displacement | 0.01mm | |||

Drive system | ||||

Motor | AC servo-motor | |||

Test speed(mm/min) | 0.001-1000 | 0.001-500 | ||

Speed accuracy | within ±0.1% of set speed | |||

Power supply | AC220V±10%, 50Hz/60Hz(can be customized) | |||

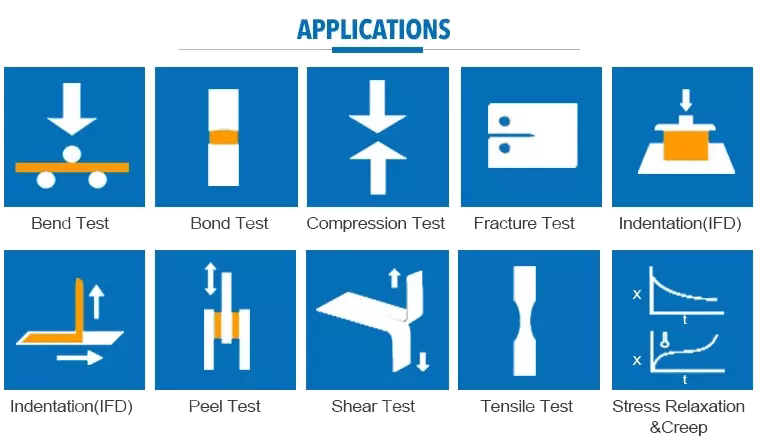

Standards

ASTMA370,ASTME4,ASTME8,ASTME9,

ISO6892,ISO7438,ISO7500-1,EN10002-4,

GB/T228-2002, GB 16491-2008, HGT 3844-2008 QBT 11130-1991, GB13-22-1991, HGT 3849-2008,GB6349-1986, GB/T 1040.2-2006, ASTM C165, EN826, EN1606, EN1607, EN12430 etc

Main frame

1. High and low temperature tests can be carried out using thermal chambers, ovens, cooling systems, etc. a along with its special testing fixtures.

2. Machine base hosts the lower crosshead, the servomotor as well as the screw-ball driven mechanical transmission system.

3. Two guiding columns (chrome coating) and two high precision ball-screw drivers, assures an optimum load share and optimal linear mobile crosshead displacement.

4. Upper crosshead designed for frame stabilization and stifness. On demand it can be designed to allow a secondary testing frame over the mobile crosshead.

5.  End of stroke detectors (adjustable) and visual positioning ruler placed along the frame.

End of stroke detectors (adjustable) and visual positioning ruler placed along the frame.

Parts identification

1. Fixed upper crosshead: to provide test frame

2. Stiffness

3. Mobile crosshead: actioned by the screw drivers. Applies the load against the test specimen.

4. Aluminium alloy housing: to host and protect screw drivers

5. Gripping heads. Other gripping heads and testing fixtures are available

6. Load cell. Universal type (tensile-compression)

7. High precision transducer for measure of the

8. crosshead position. mounted on the ball-screw axis.

Safety Device

1. Stroke protection: Machinery,computer double

2. protection, prevent over preset

3. Force protection: system setting

Emergency stop device: handing emergencies

Standard Accessories | Optional configurations |

Host | |

Wedge Grip V-jaws for round samples, Ф4-Ф9 Flat jaws, 0-7mm | Wedge Grip V-jaws for round samples, Ф9-Ф14 Flat jaws with opening, 7-14mm |

Compression Grip Platen Ф100mm | Other Fixture Bending Fixture |

Ball Screw Precision Ball Screw | |

Panasonic AC Servo motor | |

Test control system | Optional |

Sensor High precision load sensor | US Celtron spoke load sensor |

LCD controller | Touch screen display |

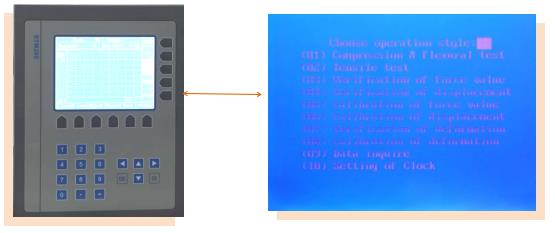

LCD Controller Function Features

1. Automatic calibration: system can automatically realize the accuracy of the calibration value.

2. After the sample broken, automatic stop.

3. Automatic display: Real-time display testing force, displacement, testing speed, peak value, testing status on one LCD.

4. Automatic return: beam automatic return to initial position when testing finished.

5. Breakage judgment: sample after fracture,beam automatic stop moving

6. Limiting protection: Program control and Mechanical limiting protection.

7. Overload protection: When more than 3 ~ 5% of the rated load device automatically stop working.

8. Automatic calculation: automatic calculation area after input sample diameter (round); Width, thickness (flat), sample gauge ect.

Specification:

Model | UTM-10ED | UTM-20ED | UTM-30ED | UTM-50ED |

Load frame | ||||

Max. Load(kN) | 10 | 20 | 30 | 50 |

Tensile space(mm) | 800 (can be customized) | 700 (can be customized) | ||

Compression space(mm) | 800 (can be customized) | 700 (can be customized) | ||

Test width(mm) | 400 (can be customized) | 500 (can be customized) | ||

Travel distance(mm) | 1140 | |||

Working temperature | +10 ... +35 °C | |||

Conformity | ISO 9000 and CE | |||

Force transducer | ||||

Load accuracy | Class 1 | |||

Load range | 2%~100%F·S | |||

Load resolution | 1/500000 | |||

Displacement transducer | ||||

Resolution of deformation | 0.04um | |||

Accuracy of displacement | Within±0.5%of indicating load | |||

Resolution of displacement | 0.01mm | |||

Drive system | ||||

Motor | AC servo-motor | |||

Test speed(mm/min) | 0.001-1000 | 0.001-500 | ||

Speed accuracy | within ±0.1% of set speed | |||

Power supply | AC220V±10%, 50Hz/60Hz(can be customized) | |||

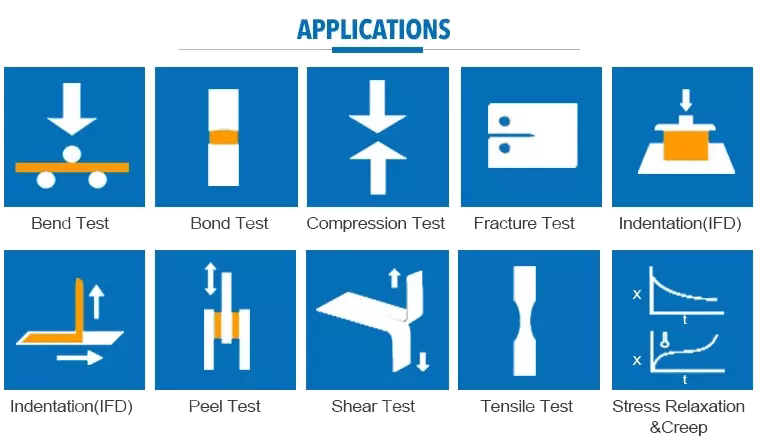

Standards

ASTMA370,ASTME4,ASTME8,ASTME9,

ISO6892,ISO7438,ISO7500-1,EN10002-4,

GB/T228-2002, GB 16491-2008, HGT 3844-2008 QBT 11130-1991, GB13-22-1991, HGT 3849-2008,GB6349-1986, GB/T 1040.2-2006, ASTM C165, EN826, EN1606, EN1607, EN12430 etc

Main frame

1. High and low temperature tests can be carried out using thermal chambers, ovens, cooling systems, etc. a along with its special testing fixtures.

2. Machine base hosts the lower crosshead, the servomotor as well as the screw-ball driven mechanical transmission system.

3. Two guiding columns (chrome coating) and two high precision ball-screw drivers, assures an optimum load share and optimal linear mobile crosshead displacement.

4. Upper crosshead designed for frame stabilization and stifness. On demand it can be designed to allow a secondary testing frame over the mobile crosshead.

5.  End of stroke detectors (adjustable) and visual positioning ruler placed along the frame.

End of stroke detectors (adjustable) and visual positioning ruler placed along the frame.

Parts identification

1. Fixed upper crosshead: to provide test frame

2. Stiffness

3. Mobile crosshead: actioned by the screw drivers. Applies the load against the test specimen.

4. Aluminium alloy housing: to host and protect screw drivers

5. Gripping heads. Other gripping heads and testing fixtures are available

6. Load cell. Universal type (tensile-compression)

7. High precision transducer for measure of the

8. crosshead position. mounted on the ball-screw axis.

Safety Device

1. Stroke protection: Machinery,computer double

2. protection, prevent over preset

3. Force protection: system setting

Emergency stop device: handing emergencies

Standard Accessories | Optional configurations |

Host | |

Wedge Grip V-jaws for round samples, Ф4-Ф9 Flat jaws, 0-7mm | Wedge Grip V-jaws for round samples, Ф9-Ф14 Flat jaws with opening, 7-14mm |

Compression Grip Platen Ф100mm | Other Fixture Bending Fixture |

Ball Screw Precision Ball Screw | |

Panasonic AC Servo motor | |

Test control system | Optional |

Sensor High precision load sensor | US Celtron spoke load sensor |

LCD controller | Touch screen display |

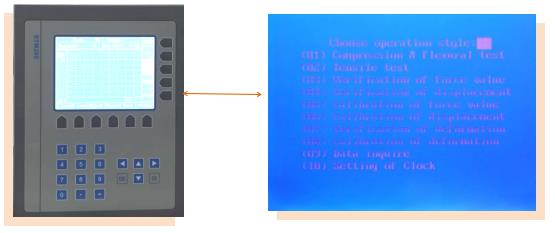

LCD Controller Function Features

1. Automatic calibration: system can automatically realize the accuracy of the calibration value.

2. After the sample broken, automatic stop.

3. Automatic display: Real-time display testing force, displacement, testing speed, peak value, testing status on one LCD.

4. Automatic return: beam automatic return to initial position when testing finished.

5. Breakage judgment: sample after fracture,beam automatic stop moving

6. Limiting protection: Program control and Mechanical limiting protection.

7. Overload protection: When more than 3 ~ 5% of the rated load device automatically stop working.

8. Automatic calculation: automatic calculation area after input sample diameter (round); Width, thickness (flat), sample gauge ect.